The Problem

An East Coast label printing plant needed to upgrade its regenerative thermal oxidizer (RTO). The 3-canister RTO packed with ceramic saddles was achieving approximately 93% thermal efficiency at 17,000 scfm, but the plant now needed to treat 24,000 scfm of VOC-laden exhaust air..Why MLM-200® was Used

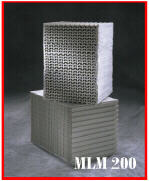

The alternatives were to purchase a new RTO or to retrofit the existing equipment with multi-layer media (MLM) from Lantec Products. In order to avoid a major capital expenditure, the decision was made to retrofit the system.

Meeting the Requirements

In early June 1998, the 8’ 6” bed of 1” saddles in each heat-recovery canister were replaced with 3’ 8” of MLM-200. The results of the retrofit met all ex-pectations. During continuous operation at superficial gas velocities exceeding 375 scfm/ft2, the thermal efficiency was actually improved to 94.6%, and overall pressure drop reduced. All applicable emission standards were met. The RTO is now operating at 24,000 scfm, but the MLM-200 will allow future expansion up to 28,000 scfm.